How to break through the technical bottleneck of new energy vehicle battery thermal management parts? To break through the technical bottleneck of thermal management parts for new energy vehicle batteries, we need to make concerted efforts in four dimensions, namely, material innovation, system integration, intelligent control and environmental protection design, and the specific strategies are as follows:

The use of graphene, copper foil and other high thermal conductivity materials can significantly improve the internal heat transfer efficiency of the battery. For example, the thermal conductivity of graphene is as high as 5300W/m-K, which is several times higher than that of traditional aluminium, and can effectively reduce the temperature difference inside the battery module and reduce the risk of local overheating.

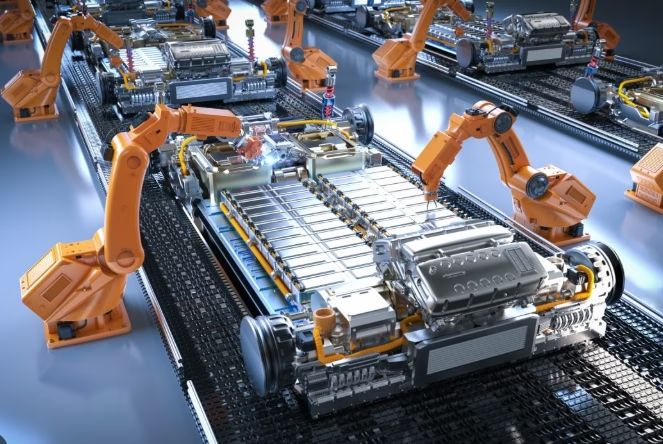

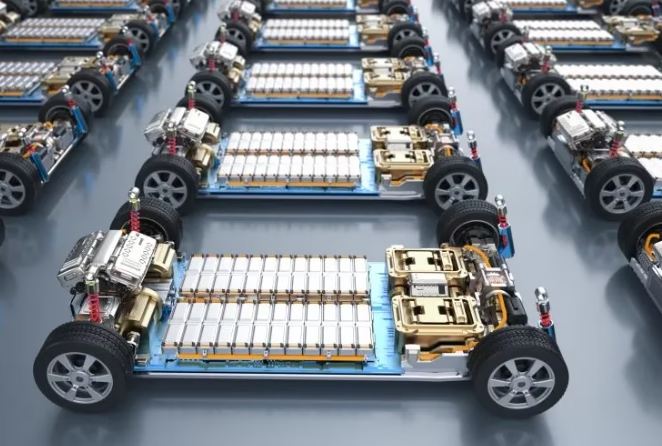

The battery thermal management system is highly integrated with the battery module and electronic control system, reducing the number of piping connections and components, and lowering system complexity and cost. Adoption of one-piece casting and welding process manufacturing technology, which can realise the miniaturisation and lightweighting of the thermal management module.

Designing a heat recovery system to recycle waste heat generated by batteries, motors, etc. for cockpit heating or battery insulation. Tesla’s heat pump air-conditioning system is controlled by an eight-way valve to achieve efficient recycling and utilisation of waste heat, improving the energy efficiency of the entire vehicle.

High-precision temperature sensors are arranged inside the battery module to monitor the battery temperature, voltage and other parameters in real time and analyse the data in combination with intelligent algorithms. The system can adjust the cooling or heating strategy in advance to keep the battery within the optimal working temperature range.

According to the real-time status of the battery and changes in the external environment, the working status of the heat dissipation system is automatically adjusted. In high-temperature environments, the system can automatically increase the coolant flow and fan speed to improve cooling efficiency; in low-temperature environments, it can activate heating elements to preheat the battery.

How to break through the technical bottleneck of new energy vehicle battery thermal management accessories? Optimise structural design and adopt new materials to reduce the weight and volume of thermal management system. The use of ultra-thin runner plates and integrated design can reduce the space occupied by the system and improve the energy density and range of the whole vehicle.

Leave a Reply