How does thermal management system affect the performance of new energy vehicles? The impact of thermal management system on the performance of new energy vehicles extends across battery life, driving safety and user experience, and is one of the core technologies that determine the competitiveness of the entire vehicle. The following is an analysis of the impact of the thermal management system on vehicle performance:

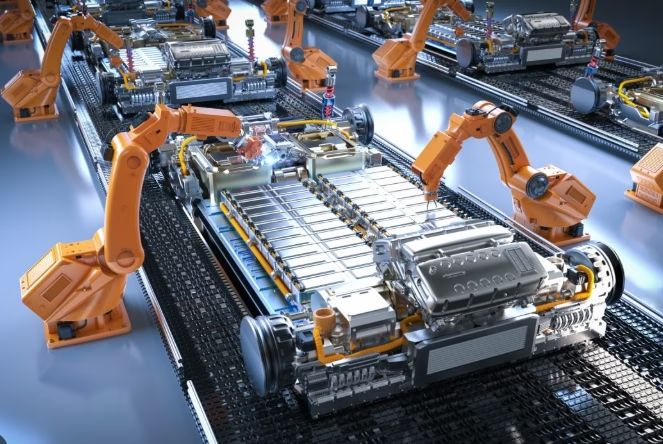

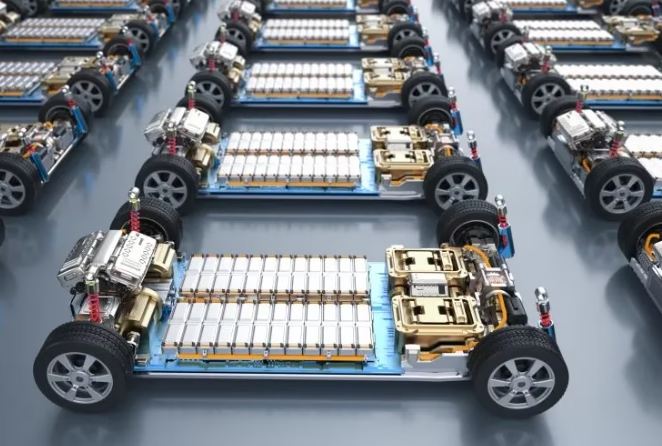

As a core component of new energy vehicles, battery performance is significantly affected by temperature. When the battery is in a low-temperature environment, the ion conduction rate decreases, and the charging and discharging efficiency decreases, resulting in a significant reduction in vehicle range. When the temperature of the battery is too high, the internal chemical reaction accelerates, which not only aggravates the decline of battery capacity and shortens its cycle life, but also triggers the risk of thermal runaway, resulting in serious safety accidents, such as smoke, fire and even explosion.

The thermal management system for new energy vehicles actively regulates the temperature of the battery, controlling it in the optimal operating range of 15°C-35°C. In low-temperature environments, the system uses the battery temperature to control the temperature of the battery. In low-temperature environments, the system uses heating film, heat pumps and other technologies to preheat the battery and improve its charging and discharging efficiency; in high-temperature environments, the system dissipates heat through liquid cooling, air cooling and other means to prevent the battery from overheating.

The energy consumption of the thermal management system directly affects the range performance of new energy vehicles. Traditional PTC heating solutions have high energy consumption, while heat pump technology achieves efficient heating through heat transfer, with a COP of up to 2-3, saving more than 50% energy compared to PTC solutions. Some high-end models are equipped with heat pump systems that, combined with motor waste heat recovery technology, can control range degradation to less than 15% in winter.

The thermal management system reduces energy waste by optimising heat distribution. In winter, the system can recycle the waste heat generated by the motor and electronic control for battery insulation or in-vehicle heating, realising the graded utilisation of energy. The energy efficiency of the system can be further improved by optimising the design of the cooling circuit and reducing the power consumption of components such as water pumps and fans.

How does a thermal management system affect the performance of a new energy vehicle? Under extreme operating conditions, such as prolonged hill climbing or high-speed cruising, thermal management systems can prevent critical components from overheating by enhancing heat dissipation. For example, some models adopt a dual cooling circuit design to dissipate heat independently from the battery and motor electronic control, ensuring system stability under high loads.

Leave a Reply