How durable are Li Auto’s eco-friendly body components? The durability of Li Auto’s eco-friendly body components can be comprehensively evaluated across three dimensions: material selection, process innovation, and real-world validation.

Hot-formed aluminum-silicon-coated panels feature a dense oxide layer formed through specialized processes, effectively blocking moisture and salt penetration to delay corrosion progression. All metal body components undergo rigorous salt spray testing to ensure structural integrity during prolonged use in coastal or high-humidity regions.

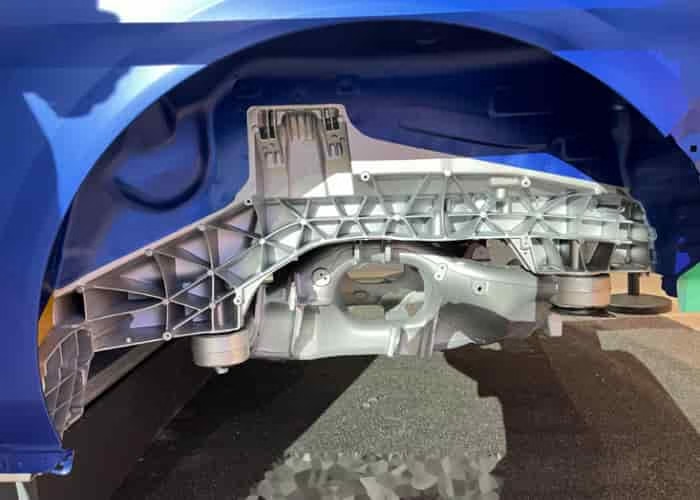

Li Auto has revolutionized traditional passivation methods by integrating eco-friendly passivation into the die-casting part cleaning line. By developing a novel eco-friendly passivation solution, Li Auto replaces heavy metal chromium with zirconium and incorporates high-molecular polymers to enhance interfacial bonding, resulting in a denser and more uniform passivation layer.

This innovation not only resolves the industry-wide challenge of “white fuzz” growth on cast aluminum parts but also reduces production costs through integrated processes. Corrosion resistance testing confirms this process significantly enhances the anti-corrosion capability of exposed cast aluminum components, extending their service life.

Real-world validation data from extreme climates further confirms durability. After prolonged use, vehicles exhibited no corrosion-induced perforations or component failures. Units exported to high-salinity regions also demonstrated stable performance, with no structural damage attributed to environmental factors.

How durable are Li Auto’s eco-friendly body components? Considering material performance, process innovation, and real-world validation, these components demonstrate high durability standards, setting an industry benchmark for balancing environmental sustainability with long-term reliability.

Leave a Reply