As electric vehicle owners move from early adopters to mainstream consumers, service centers are facing a new kind of challenge. Customers have strong opinions about how electric vehicle batteries work, but lack adequate information. Here are common customer misconceptions about electric vehicle batteries and the realities that service professionals at dealerships and independent repair shops need to explain.

Myth 1: Electric vehicle batteries don’t degrade

One of the most common misconceptions is that electric vehicle batteries don’t degrade. This notion often stems from marketing claims such as “1,000 km of battery life” or extended battery warranties, which imply permanent stability in battery performance. But the truth is simple: All lithium batteries degrade over time. Each charge and discharge cycle slightly reduces the battery’s capacity, and thermal stress (stress caused by uneven temperatures within an object) caused by the vehicle’s operating temperature and internal heat generation accelerates this process.

Under normal driving conditions, most electric vehicles experience battery degradation of about 2% to 3% per year. Advanced battery management systems can mitigate this problem by controlling charge levels, regulating temperature, and protecting cells from overvoltage. However, battery degradation is inevitable and accumulates with age, usage patterns, and charging habits.

Inform customers that battery degradation is expected and does not necessarily mean the battery is faulty. Tools that can measure the battery’s actual state of health (SOH) can provide service departments with data to help them communicate better.

Myth 2: EV batteries don’t need to be repaired, they can just be replaced

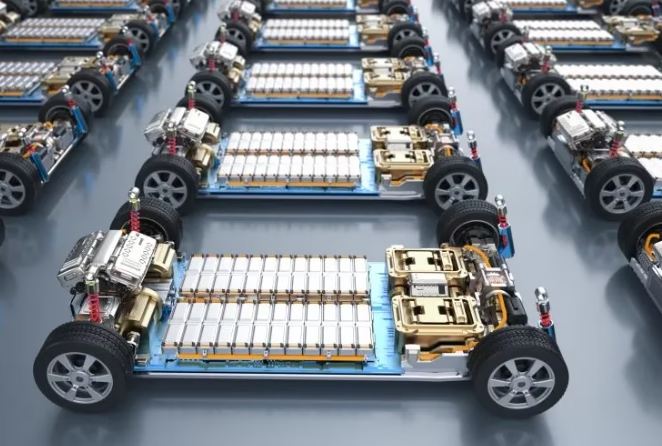

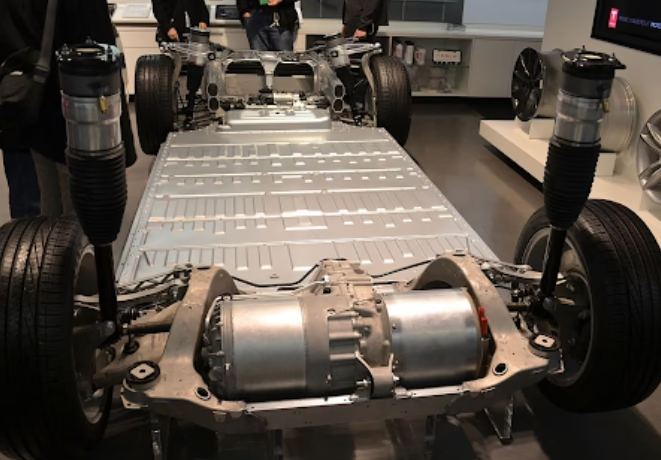

Many customers (and some technicians) believe that if there is a problem with the battery, the only option is to replace it completely. This misconception likely stems from the high cost of battery packs and the fact that most battery packs are sealed and not easily disassembled. However, in reality, most EV battery packs are modular and many problems can be fixed without replacing the entire pack.

Common repairable issues include coolant leaks, damaged internal connections, sensor failures, or individual module failures. As manufacturers continue to improve their service strategies, more and more manufacturers support component-level battery repairs, especially to control warranty costs. With the right diagnostics, it is possible to pinpoint the fault and determine whether a repair is safe and cost-effective.

Service teams should resist the urge to replace the battery directly. Some advanced tools, such as Midtronics’ GRX-5100, allow for detailed analysis and decision making on repairs.

Myth 3: Every fast charge damages the battery

The fear that fast charging can damage EV batteries is deeply ingrained in the world of consumer electronics. Remember how quickly your cell phone battery degrades after a fast charge or when it’s left plugged in overnight? But EVs are designed with more robust battery management systems that actively monitor battery temperature, voltage, and charging speed.

Frequent fast charging does increase long-term battery wear, especially at high temperatures. The reason is heat—the rapid current during DC fast charging generates more heat, and repeated thermal stress shortens battery life. The key word, however, is “frequent.” Occasional fast charging, especially on long trips, is perfectly safe.

Rather than warning customers against fast charging altogether, service professionals should educate them on balanced charging habits. Encourage daily use of AC slow charging and explain how built-in systems protect the battery during high-speed charging.

Myth 4: You must charge to 100% for optimal performance

This problem stems from “tank thinking.” People are used to “filling up the tank completely.” However, for EVs, charging to 100% every day can actually reduce the long-term health of the battery. The first 10% of a lithium battery’s charging range puts the most electrical stress on the battery, and keeping it at 100% state of charge (SOC) for long periods of time accelerates battery aging.

Most automakers now recommend charging to 80% for daily driving and 100% for long drives. Many EVs even allow drivers to set target SOC limits to reduce unnecessary stress. Preconditioning also ensures that the battery is at the right temperature during charging and use.

Service personnel can reinforce this with door-to-door service visits. Spending a few minutes explaining charging habits can avoid range complaints later and help customers extend the life of their batteries.

Myth 5: Cold weather damages EV batteries

Customers often suspect something is wrong with their EVs in the winter because their EV range drops significantly. What they’re seeing is not permanent damage, but a natural reaction to cold temperatures. At low temperatures, the chemical reactions inside lithium batteries slow down, reducing energy output and charging speed.

Modern EVs combat this with thermal management systems that preheat the battery before use or when plugged in. The performance drop is temporary and will improve once the battery reaches its ideal operating temperature. Cold temperatures do not “kill” the battery, they simply limit its efficiency until the battery warms up.

Service professionals should demonstrate to customers how to use the scheduled departure or preheat features. If the range is still abnormally low even after preheating, further diagnostics may be needed, but most of the time, this is just physics.

Myth 6: EV Batteries Are Unsafe and Prone to Fire

EV battery fires are a high-profile occurrence. The causes of fires are complex, difficult to extinguish, and often make sensational headlines. But statistically, EVs are less likely to catch fire than internal combustion engine vehicles. What is really concerning is the nature of the battery fire when it does occur. Fires can be violent and can even cause thermal runaway, which, even if rare, can seem catastrophic.

Battery safety has improved significantly over the past decade. Battery designs include internal fuses, fire barriers, and ventilation systems. Battery management system (BMS) software continuously monitors for overvoltage, overcurrent, and overheating conditions and shuts down the system when necessary. In the event of a crash, most EVs automatically isolate the battery to prevent arcing.

Nevertheless, damaged batteries still need to be handled with care. Technicians need high-voltage training, safety equipment, and clear post-crash inspection procedures. Informing customers of these safety measures can ease their concerns and ensure that risks are manageable and rare.

Myth 7: Battery diagnostics are like internal combustion engine (ICE) vehicle diagnostics

Some service technicians approach EV battery issues the same way they would test an alternator or starter. Plug it in, check the voltage, and replace it if it’s low. But EV battery diagnostics are far more complex than that. Technicians need to analyze module-level voltages, temperature factors, internal resistance, and historical charge and discharge data. That’s not an easy task.

Traditional scan tools aren’t designed for this level of detail. Dedicated platforms like Midtronics’ EV diagnostics are designed to read battery management system (BMS) data, detect imbalances between modules, and identify hidden faults that could affect range or safety. Without the right tools, faults can go undetected or be misdiagnosed.

Using real batteries just sets the record straight

The rumors about EV batteries are not groundless. They affect how consumers drive, charge, and perceive the reliability of their vehicles. If left unchecked, these rumors could undermine trust in the technology and the repair shop’s ability to perform repairs.

The future of EV service depends on eliminating confusion. That means using real diagnostic data, providing clear explanations, and investing in the right tools and training. At Midtronics, we’re supporting this shift by working on diagnostic and repair tools that meet today’s EV challenges and tomorrow’s.

The bottom line: When you tell the truth about EV batteries and show the proof, you’re not just fixing the car, you’re building confidence.

Common customer misunderstandings about electric vehicle batteries

Leave a Reply