New energy vehicle batteries mainly consist of four parts: cells, modules, battery packs (PACKs), and battery management systems (BMS). Their core technologies and safety designs are as follows:

I. Cells: Energy Storage Units

* Positive Electrode Materials

* Ternary Lithium (NCM/NCA): High energy density (200-300Wh/kg), but poor thermal stability, requiring a thermal management system.

* Lithium Iron Phosphate (LFP): High safety (decomposition temperature > 500℃), but lower energy density (150-200Wh/kg).

* Negative Electrode Materials

* Graphite is the mainstream material; new silicon-carbon negative electrodes can improve capacity (theoretically 10 times higher than graphite).

* Electrolyte

* Liquid electrolytes (lithium hexafluorophosphate) are flammable; solid/semi-solid electrolytes are the future trend.

II. Module: Cell Integration Unit

Structural Design: Cells are connected in series/parallel to form modules, fixed with an aluminum alloy frame. Liquid cooling plates are arranged between modules (e.g., BYD’s “module-less” CTP technology for its blade battery).

Safety Protection: Each module is equipped with a temperature sensor, which triggers the BMS to cut off power in case of an anomaly.

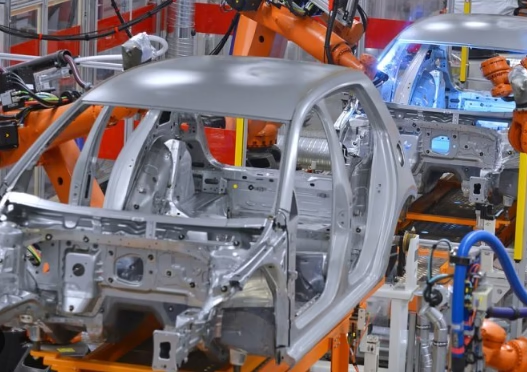

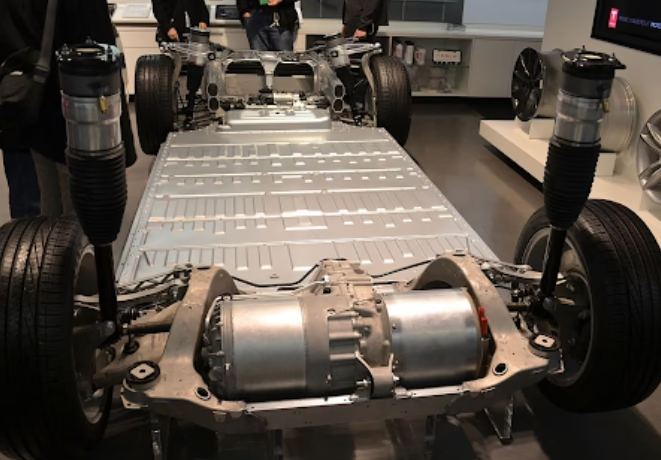

III. Battery Pack (PACK): Vehicle Integration Layer

Outer Shell Protection: Aluminum alloy/high-strength steel shell, IP67 dustproof and waterproof rating, with a steel protective plate at the bottom for scratch protection.

Thermal Management System

Liquid Cooling: Mainstream solution (e.g., Tesla’s serpentine cooling pipes), temperature control accuracy ±2℃.

Air Cooling: Low cost but low efficiency (common in early models).

IV. Battery Management System (BMS)

Core Functions: Real-time monitoring of voltage, temperature, and SOC (state of charge), balancing cell differences, and predicting thermal runaway risk.

Redundancy Design: Dual-chip architecture, with a backup system taking over in case of main controller failure (e.g., NIO ET7). Technology trends: 4680 large cylindrical cells (Tesla), sodium-ion batteries (CATL), and solid-state batteries (Toyota’s mass production in 2027) will further improve safety and energy density.

Leave a Reply