What are the main components of electric vehicles? As the roar of the fuel vehicle era fades away, electric vehicles are reconstructing the genetic map of the automotive industry with precise scientific and technological language. In this silent revolution, five core component systems constitute the technical foundation of electrification. They are like precisely meshed gears, driving the paradigm shift in the transportation field together.

1. Battery system: the “magic container” of energy storage

As the power source of electric vehicles, battery packs are usually made of hundreds of lithium-ion batteries in series. The mainstream ternary lithium battery provides ultra-long battery life with its energy density advantage, while lithium iron phosphate batteries become the first choice for safety due to its thermal stability. The battery management system (BMS) is like an intelligent housekeeper, monitoring the health status of each battery in real time, ensuring stable energy output through balanced control, and its algorithm accuracy directly affects the battery life and vehicle performance. The innovative structure of Tesla’s 4680 battery is a typical example of increasing energy density by 20% by optimizing space utilization.

2. Electric motor: the “invisible magician” of kinetic energy conversion

Permanent magnet synchronous motors and AC asynchronous motors constitute the two major schools of drive systems. The former is widely used in passenger cars due to its high efficiency, and its rotor magnetic field design makes the energy conversion efficiency exceed 95%; the latter relies on the principle of electromagnetic induction to show strong power output in high-speed scenarios. The motor controller uses the FOC algorithm to accurately invert DC power into three-phase AC power, achieving millisecond-level response to speed and torque. This “electric embroidery” technology enables the motor to output 400 Nm of surging torque and delicately control the vehicle’s creep.

3. Power Electronics Architecture: “Digital Symphony” of the Nerve Center

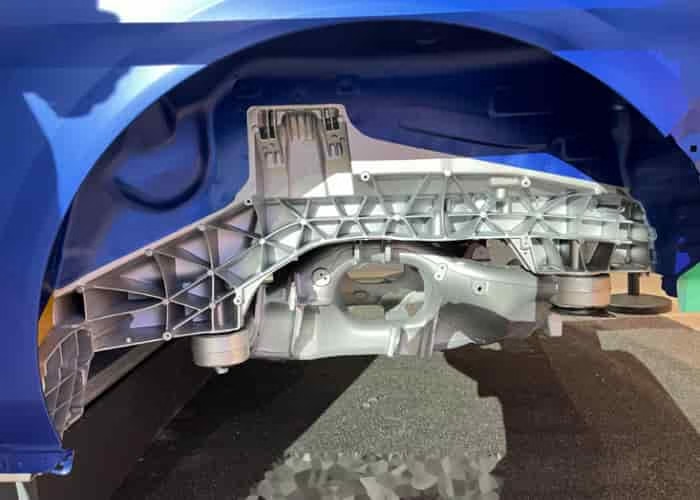

The on-board charger and DC-DC converter form an energy conversion matrix. The former rectifies the AC grid power into DC power that can be used by the battery, and the latter provides a stable power supply for the low-voltage system. As the power heart, the inverter uses SiC (silicon carbide) modules to replace traditional silicon-based devices, which increases the switching frequency by 10 times and the system efficiency exceeds 98%. This material revolution not only reduces energy consumption, but also reduces the size of the controller by 40%, freeing up valuable space for chassis layout.

4. Thermal management system: the “lifeguard” of temperature balance

Battery thermal runaway is the sword of Damocles hanging over the safety of electric vehicles. The liquid cooling system controls the battery temperature difference within 3°C through a precisely designed flow channel structure. As a model of energy recycling, heat pump air conditioning can convert motor waste heat for heating in winter, and its energy efficiency is 300% higher than that of traditional PTC. Some models are more innovative in using phase change materials, using the heat absorption characteristics of media such as paraffin during the phase change process to build a passive thermal protection barrier.

5. Intelligent driving center: the “electronic eye brain” that perceives the world

Millimeter wave radar and laser radar constitute a multimodal perception network. The former is good at target speed measurement, and the latter accurately constructs a three-dimensional point cloud. As the decision-making brain, the domain controller integrates visual data from 12 cameras and recognizes more than 200 types of traffic participants in real time through a deep learning model. The wire-controlled chassis system makes steering and braking fully digitized, and with high-precision maps, centimeter-level path planning is achieved. This kind of software and hardware collaboration is driving the evolution of automobiles from transportation tools to mobile smart terminals.

From precise battery thermal management to intelligent energy distribution, from optimization of motor control algorithms to iteration of autonomous driving systems, every component of electric vehicles is playing the concerto of technological evolution. When these systems break through the shackles of traditional mechanical thinking, cars finally break free from the physical limits of internal combustion engines and bloom with unprecedented innovation possibilities in the electric drive era. This revolution, which began with component innovation, will eventually reshape the DNA of the entire transportation ecosystem.

Leave a Reply