Industry breakthrough! China’s first high-density solid-state battery component officially enters mass production! Against the backdrop of the new energy vehicle industry accelerating its transition towards higher energy density and safety, China’s solid-state battery component sector has achieved a milestone breakthrough: the first high-density all-solid-state battery production line has recently entered mass production, marking China’s lead in the competition for next-generation power battery technology.

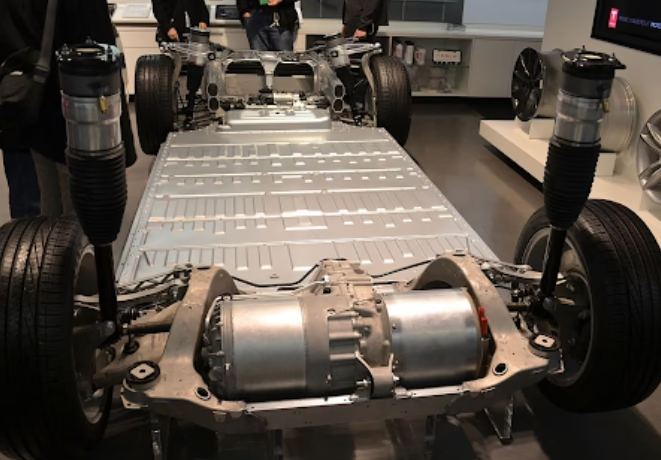

Traditional liquid batteries rely on organic electrolytes to transport lithium ions, but liquid components are prone to thermal runaway at high temperatures or when punctured. In contrast, solid-state electrolytes, with their non-flammable and high-temperature-resistant properties, significantly raise the thermal runaway critical temperature, thereby reducing safety risks at their source. Solid-state electrolytes are compatible with high-capacity materials such as metallic lithium anodes, enabling a significant increase in energy density compared to existing liquid batteries, laying the foundation for ultra-long-range electric vehicles.

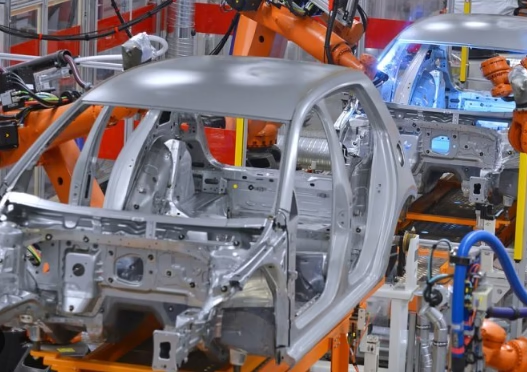

The newly mass-produced all-solid-state battery component production line has achieved disruptive innovation in manufacturing processes. Traditional liquid battery production requires over ten core processes, while the new production line uses dry electrode manufacturing technology to drastically reduce the number of processes and replaces the traditional electrolyte filling step with an integrated moulding process. This not only reduces safety hazards caused by electrolyte evaporation but also lowers production energy consumption.

To address the stability issues at the interface between the solid-state electrolyte and electrodes, the R&D team employed nanoscale surface modification technology to create a stable solid-state electrolyte interface layer on the electrode material surface, effectively suppressing lithium dendrite growth and extending battery cycle life.

The introduction of new skeleton membrane materials not only enhances the mechanical strength of the solid-state electrolyte but also optimises lithium-ion transmission pathways through a porous structure design, enabling the battery to perform significantly better than traditional liquid batteries in low-temperature environments. From an industrial application perspective, the mass production of all-solid-state battery components will accelerate the high-end development of new energy vehicles.

The high safety characteristics meet aviation-grade airworthiness standards, providing power support for low-altitude economic sectors such as electric vertical take-off and landing aircraft; the high energy density can drive breakthroughs in the range of new energy vehicles, alleviating users’ range anxiety. As large-scale production progresses, the cost of solid-state battery components is expected to gradually decrease, driving the technology’s penetration from high-end models to the mainstream market.

Industry breakthrough! China’s first high-density solid-state battery component has officially entered mass production! This mass production not only reflects the innovative capabilities of China’s battery industry but also signals a reshaping of the global competition landscape in new energy technology. The iteration speed of solid-state battery components will continue to accelerate, injecting strong momentum into the high-quality development of the new energy vehicle industry.

Leave a Reply