As a core component, the battery of a new energy vehicle has a direct impact on the vehicle’s range and service life.

When a new energy vehicle battery fails, does it mean that it cannot be repaired and can only be replaced? In fact, battery repair is not impossible, and its feasibility depends on many factors. Next, we will explore the feasibility of new energy vehicle battery repair and related issues.

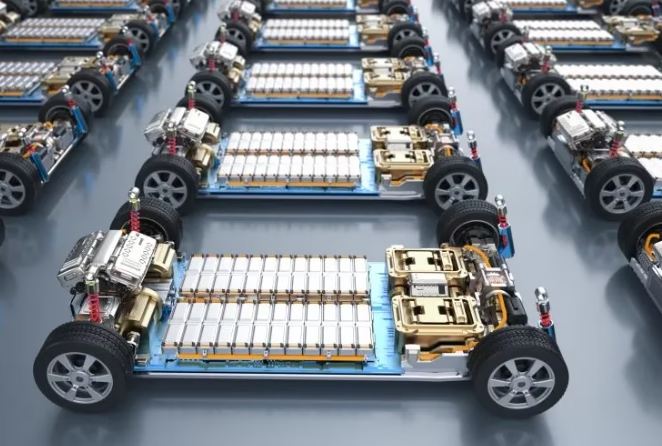

New energy batteries are often composed of multiple battery modules, and these battery packs are usually not repairable individually. However, the batteries of some new energy vehicle models are designed as a group of battery packs, which can be replaced individually.

How to diagnose the performance of battery failure? How to repair?

The most commonly used tools at present include: cycle charge and discharge equipment, battery equalizer, battery capacity test, battery internal resistance test, etc.

Cyclic charge and discharge: As the main energy storage method for modern electronic devices and electric vehicles, the charge and discharge characteristics of lithium batteries are crucial to energy management. The charge and discharge curve is an important indicator that describes the voltage and current changes of lithium batteries during charging and discharging. The life of a lithium battery is closely related to its charge and discharge curve. By monitoring and analyzing the changes in the charge and discharge curve, the health of the battery cell can be judged and the faulty battery cell can be located.

The charge and discharge curve of lithium batteries can also be used for fault detection and early warning. When the charge and discharge curve shows abnormal changes, such as severe voltage fluctuations or sudden current changes, it may mean that there is a problem with the battery. By timely monitoring and analyzing these curve characteristics, battery failures can be discovered in advance and corresponding measures can be taken to avoid further damage.

In-depth analysis and application of lithium battery charge and discharge curves help to better understand and manage the performance and use of lithium batteries. By understanding the basic principles of charge and discharge curves and combining them with practical applications such as power management, battery life prediction and fault detection, we can optimize power management strategies and improve battery life and safety.

Battery balancing: In theory, these single cells should have exactly the same characteristics, but in fact, due to fluctuations in process parameters related to manufacturing and production processes, even lithium-ion batteries from the same batch still have certain differences in performance.

After combined welding, the direction and length of the connecting piece and the influence of the welding process will increase the difference.

In the long-term use process, continuous charging and discharging will lead to uneven performance between single cells. The difference between each battery cell will gradually increase. The actual capacity of the battery pack depends on the capacity of the smallest battery cell. The difference in battery cell capacity will directly affect the driving range.

At this time, the battery needs to be balanced. The main function of balancing is to consume or transfer the power of the pre-charged single battery during the charging and discharging process, so that other cells that have not been fully charged or discharged can continue to charge, thereby ensuring that the battery pack as a whole can be charged more fully.

Because the balancing system of the battery pack is inefficient, inaccurate, and ineffective, it is difficult to meet the needs of battery balancing. Maintenance personnel usually use battery equalizers to maintain battery performance and improve the actual capacity of the battery pack.

Battery capacity test: Battery capacity is one of the most important indicators of the battery. A new battery can be considered to be in the best state in terms of capacity and performance. As the number of charge and discharge cycles increases, the battery capacity will gradually decay. Assuming that a battery has a capacity of only 80% of its original design capacity after long-term use, the battery health (SOH) can be obtained as 80%. Battery health (SOH) is an important indicator used to measure the performance and life status of lithium batteries, usually indicating the ratio of the current battery capacity to the new battery capacity.

The battery capacity grading equipment mainly measures the battery capacity. Combined with the factory indicators of the battery, the current health of the battery can be calculated.

For the battery cells, battery modules, and whole packs of batteries that have been removed from the car, in the battery maintenance process, it is necessary to eliminate over-aged batteries by measuring capacity and health, and select consistent batteries for grouping or replacement. Therefore, the capacity grading equipment is crucial for the battery maintenance process.

Battery internal resistance test: The internal resistance of the battery is one of the most important characteristic parameters of the battery. It is an important parameter to characterize the battery life and battery operating status, and it is an important indicator to measure the difficulty of electrons and ions in the electrode transmission. The internal resistance also reflects the health of the battery. The internal resistance of the battery is very small when it leaves the factory, but after long-term charging and discharging, due to the loss of electrolyte inside the battery and the decrease in the activity of chemical substances inside the battery, the internal resistance will gradually increase. The electrolyte will gradually degenerate during multiple charging and discharging, and the internal resistance will increase until the internal resistance is so large that the power inside the battery cannot be released normally. At this time, the battery is aged and the relative battery capacity will also decrease.

The impact of internal resistance on battery performance is reflected in many aspects. In terms of discharge capacity, when the internal resistance is large, the internal power loss of the battery increases, the actual output power decreases, and the power performance of the battery is affected; in terms of charging efficiency, high internal resistance will lead to increased energy loss, slower charging speed, and lower charging efficiency; in terms of battery life, increased internal resistance causes heat, accelerates the aging of chemical substances inside the battery, and shortens the battery life. When the internal resistance of the battery is too large or the internal resistance of individual cells is inconsistent, it causes local overheating of the battery and accelerated aging of some cells. It will bring great safety hazards to the entire battery.

In short, internal resistance is also one of the essential test indicators when repairing the battery.

Leave a Reply