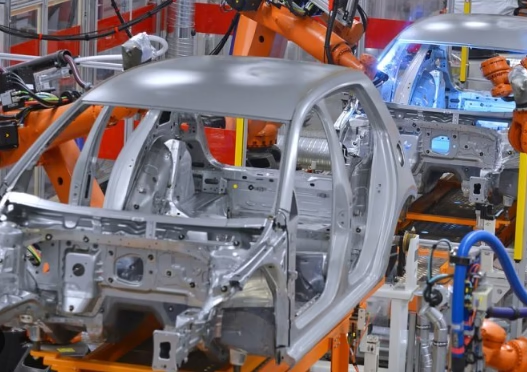

In the Zunjie Super Factory jointly built by JAC Motors and Huawei, more than 1,800 intelligent robots are working to achieve full automation and digitalization of stamping, welding, painting, and assembly workshops. With the help of self-developed algorithms and industrial-grade monitoring robots, AI visual inspection is performed on 1,500 key points, and the detection accuracy of minor appearance defects can reach 0.2 mm;

In the Xinqiao Second Factory of NIO Advanced Manufacturing, some manufacturing scenarios have realized AI intelligent decision-making. On large and small intelligent assembly islands, sunroofs, front and rear windshields and other parts are assembled “in parallel”. The assembly plan has changed from “one-way street” to “overpass”. Multiple platforms and multiple models can be produced online at the same time, and an average of one car is produced per minute…

On July 1, reporters participating in the “Vibrant China Research Tour” theme interview activity came to the factory workshop and sighed that technology empowerment has allowed China’s “smart” manufacturing to leap to a new height and also accelerated the “running” of new energy vehicles.

Hefei is an important gathering place for the new energy vehicle industry. Six vehicle companies including JAC, BYD, NIO, and Volkswagen have settled here, leading the high-quality development of the industrial cluster with the scale effect of the whole vehicle. A set of data confirms the vitality of industrial development: As the only “four pilot” city in the country for new energy vehicle “battery replacement”, “dual intelligence”, industrial chain supply chain system, and “vehicle-road-cloud integration”, Hefei produced 1.9116 million vehicles last year, of which 1.376 million were new energy vehicles, an increase of 84.4% year-on-year, and the local production ranked first among cities in the country. Recently, the new Xiaomi YU7 model has been selling well, and BYD’s Brazilian production base has officially started construction… A series of new developments in the automotive industry have attracted global attention. Where does the confidence of more “Made in China” cars from rising to leading come from? One of the outstanding feelings of the reporter’s investigation in Anhui is that innovation has become the key gene supporting the development of China’s automotive industry. Technological innovation allows the battery system and chips on the automotive “chain” to continue to iterate and upgrade, making the smart cockpit and in-vehicle software more and more “smart”, and also brings changes to the production line, so that the logic of automobile manufacturing has been upgraded from “physical superposition” to “intelligent symbiosis”. The reporter saw at the scene that NIO’s world-first “magic cube” vehicle storage and retrieval platform is like a giant intelligent “claw doll” machine. In the 6-story and 750-plus parking spaces, the car bodies of different colors do not need to be “first in, first out”, but “grabbed” on demand according to the order.

“High flexibility enables rapid response to personalized production, greatly improving production efficiency.” Li Bin, founder, chairman and CEO of NIO, said that this is based on the entire “Tiangong” intelligent manufacturing management system, which can trace the entire process of huge real-time data streams.

The luxury new energy sedan Zunjie S800, which has been on the market for only more than a month, has received hot orders, and its dual-color body design is a highlight. This is due to the industry’s first dual-color automatic color separation robot, which uses AI visual positioning and force control systems to control the color separation line accuracy within 0.3 mm.

“Innovative technology research is painful and joyful.” Luo Shicheng, assistant to the general manager of JAC Motors, said that the two-color process, which took more than half a year to achieve, not only puts extremely high demands on the consistency of the car body, but is also closely related to training AI models and allowing the robotic arm to accurately control the spraying force.

“The breakthrough from 0 to 1 is inseparable from the deep integration of joint research and development of the supply chain and cross-border technology.” Li Ming, general manager of JAC Motors, told reporters that more than 200 suppliers from more than ten provinces across the country are involved in the production and roll-off of a Zunjie S800. Upstream and downstream partners grow together in the high-end breakthrough of the industrial chain, driving the entire chain to achieve multi-dimensional leaps in technology, quality, craftsmanship and experience.

Within a radius of less than 20 minutes’ drive from JAC Motors’ vehicle plant, many supply chain companies are gathered. Hua Ting (Hefei) Power Technology Co., Ltd. is one of them. This leading independent third-party pack company in China has currently produced more than 2 million power battery systems.

The reporter saw in the production workshop of Hua Ting Power that the processes of battery cell testing, dispensing, welding, etc. were carried out in an orderly manner. Square or cylindrical battery cells completed the “transformation” from monomer to module and then to the whole package here, and each power battery was offline after strict performance and safety tests.

“We are located in the middle of the industrial chain, with about 20 battery cell manufacturers above and about 60 vehicle manufacturers designing power battery systems below.” Wang Yang, president of Hua Ting Power, said that the company and its partners have continuously improved product safety, reduced production costs, and strengthened the integration of industry, academia and research, and jointly built a cooperative development platform with many universities and institutes to increase the research of cutting-edge core technologies.

Adhering to the development idea of ”leading the whole with the parts”, Dai Wengang, a relevant person in charge of the Hefei Municipal Bureau of Industry and Information Technology, introduced that Hefei has comprehensively improved the resilience and thickness of the industrial chain and supply chain, and has cultivated more than 500 core parts companies such as Guoxuan High-tech, Juyi Technology, Changqing Machinery, and Huitong Holdings.

“NIO is committed to building an efficient industrial chain and continuously expanding its circle of friends. Our final assembly workshop corridor is directly connected to the factories of our supply chain partners.” Li Bin said that adhering to long-termism, pursuing common progress and win-win results, and deeply binding with partners based on high-tech and high-quality goals based on common growth is the only way to build a strong and vibrant new energy vehicle industry ecosystem.

Leave a Reply